REFINING BLADE TECHNOLOGY

– Synergistic Evolution in Flexo Print –

Featured in June 2020 Issue of FLEXO Magazine (Flexographic Technical Association)

PDF Download Available at end of below article.

The goal of every print process is to meet the needs of a print buyer. Usually, that involves print quality, turnaround time or delivery, and price.

Technical advancements made in flexography over the past 50 years allow it to best meet these needs for many print buyers in

2020. Why? The answer is multi-pronged:

- The quality of a flexographically printed dot today is competitive with any other print method

- New high-speed, wide web press technology can reliably maintain print quality at 2,000 fpm, with little startup or run waste, making flexographically printed packaging, shrink sleeves and labels less expensive

- Advances in prepress technology make flexography quicker to press, beating out other print methods on delivery—especially when last-minute changes are made

Flexography’s transformation from “second-class” to “premier” print process is the result of thousands of technical advancements spreading out over five decades. Often, improvement in one process element triggered innovation in one or more other areas. For example: As the highest anilox line counts increased from 360 mechanically engraved cells to well beyond 1,000 laser engraved cells per liner inch:

- Ink films were reduced, allowing thinner plates with smaller, more stable dots to be developed

- Mounting tapes were modified to accommodate new technology plates

- Inks were formulated to deliver density in this new environment

- Process changes prompted press manufacturers to make improvements that monitor all variables and print quality, and when needed, automatically make on-press adjustments at speed—often before a defect can occur

No “one thing” allowed flexography to advance to its present status. Instead, today’s flexo came about as a result of a synergistic evolution. Change begot change over what seemed like—but actually was not—a long period. No element in the flexographic process is the same today as in 1970. Every element has evolved.

INK METERING

Let’s take a historical perspective. In the beginning, ink was metered on the surface of a mechanically engraved and chrome plated anilox roll by a rubber roller. Some metering rolls oscillated and turned with the anilox; others, against it. At that time, flexography’s advantage was price. Cost, rather than print quality, drove buyers to flexography.

While flexography could deliver a reasonable solid or large type, two of the biggest shortcomings of the process, then and for years to come, were an inability to hold a clean dot and produce a smooth vignette. While preventing dirty print is still a focus in pressrooms, it has no comparison to the magnitude of the problem in the past.

The culprit—anilox ink film thickness! The raised dot on a plate was easily overwhelmed when it made contact with the anilox roll. The size of the dot grew again when it came into contact with the substrate, often resulting in a wider printed dot with no ink in the center—in essence, a “donut” or “halo” dot. This defect was a telltale sign a job was printed flexographically, and not roto or offset. The dot was bigger, yet less dense.

To alleviate or minimize the problem, a “kiss impression” to the anilox ink film and to the substrate was advocated. In practical terms, a “plus impression” was needed at both transfer points to compensate for tolerance shortcomings in the anilox and plate cylinder’s total indicated runout (TIR) and taper. Plate and mounting tape tolerances were also an issue. If the raised image at one end of a plate was “kissing” the ink film, the other end may not have made contact. To avoid starvation, the entire raised image on a plate was pressed through the anilox ink film to touch the anilox surface. The dot became bigger as ink built up on its sides; it grew again when it was pressed into the substrate and ink squeezed out to the sides.

To address the issue of overly thick anilox ink films, the industry abandoned rubber roll metering in favor of a doctor blade— first a single wiping blade and then a single reverse angle blade. A blade in a wiping position, as used in rotogravure, was prone to hydraulic lift as speeds increased, still allowing too much ink to pass beneath the blade. In the reverse angle position, a blade sheers excess ink off the anilox, dramatically reducing the volume of ink presented to the plate. In the reverse position, the blade is less prone to hydraulic lift.

While reverse angle doctor blade ink metering was a big improvement, it didn’t go far enough. Due to the limits of mechanical engraving, the maximum anilox cell line count was 360 cells per inch. In the 1970s and 1980s, common anilox line counts for line work ranged between 180 and 240, while process counts were 300 to 360. Even when metered using a reverse angled doctor blade, these low line counts left too much ink film to maintain clean print.

LASER ENGRAVED ANILOX

Cells of mechanically engraved anilox are formed when a gearlike tool is forced into a thin malleable copper coating on the anilox surface. The teeth of the tool are a reverse of the cell being formed. Because copper is relatively soft, a thin 0.005-in. final

coating of hard chrome plate was applied to reduce wear and damage. Unfortunately, the surface was still very easy to damage. Depending on blade pressure, the chrome could wear off in a week of use.

Longer life was the original advantage of the laser engraved anilox. Ceramic could resist both damage and wear. Because a laser can burn an ink-carrying cell straight down without the sloping walls of mechanical engraved cells, a laser cell carries more ink. Gradually, laser engraved line counts increased. Process anilox went from 360 to 600 cells per inch. Increased cells could be metered to deliver required ink density from the cell, rather than the anilox surface. Eventually, line counts surpassed 1,000 per inch. Anilox ink films could be almost entirely removed. It was then possible to have plate to anilox plus impression without overwhelming the dot.

ENCLOSED INK DELIVERY

While the anilox was evolving, so was the ink metering system. Totally enclosed ink metering systems consisting of a reversed

angle doctor blade, a containment blade—in the positive or wiping position—and end seals, acting as dams at each end, that were pressed against the anilox roll. Ink was pumped into the chamber while gravity returned it to an ink pail. The amount of ink required to charge the system was 50 percent less than traditional systems. At the same time, an enclosed system reduced evaporation and contamination of ink.

BLADE MATERIAL

The fundamental job of a doctor blade is to meter or remove excess ink from the anilox surface. After all, excess anilox ink film is

at the heart of dirty print and dot gain.

In the beginning, different plastic and steel materials at varying dimensions, making contact at different angles, were evaluated to determine which one could meter best, last longest and be least damaging to the anilox surface. We learned the best metering occurs when the contact angle between the blade and anilox is set at ±35 degrees and the contact area is minimized.

Wide contact areas, even when in a reversed position, are subject to hydraulic lift, resulting in a thicker anilox surface ink film. Contact angles less than 35 degrees result in a wider contact area. Contact angles greater than 35 degrees are prone to chatter and become more abrasive and more wearing to the anilox surface.

At a 35-degree contact angle, it was determined that only steel had the rigidity to make anilox contact with the least-wide contact area. Other materials, like plastics, were not rigid enough at 0.006-in. and 0.008-in. thick. Plastics had to be thicker to achieve rigidity, resulting in a thicker, wider, contact area; hence plastic was never a real contender for use in high-quality process print, even with a stepped down tip. This is especially important when blade-to-anilox pressure is high, as so often is the case. In addition, plastic polymers would become soft and embed into the ceramic’s porosity, changing the anilox surface wettability.

SWEDISH STEEL

In 1980, a typical OEM doctor blade spec described using “the best Swedish Blue Strip Steel.” Swedish steel evolved from its long history of high-quality iron production dating back to the 16th and 17th centuries. It turned out Swedish iron ore contains the

proper percentages of trace elements to make very high-quality alloy steel. In the later part of the 19th century, Swedish steel took a leadership position in the development, production and fabrication of the metal. Today, Sweden is recognized in the world for producing among the highest-quality strip steels used for production of scientific instruments, defect-free razor blades and, more recently, doctor blades.

In the beginning, when steel was selected as the best material to precisely meter ink, it was a general-use strip steel. It performed well enough against coarse line anilox at slow press speeds. However, as anilox line counts and press speeds increased, the industry realized a more specialized steel was needed.

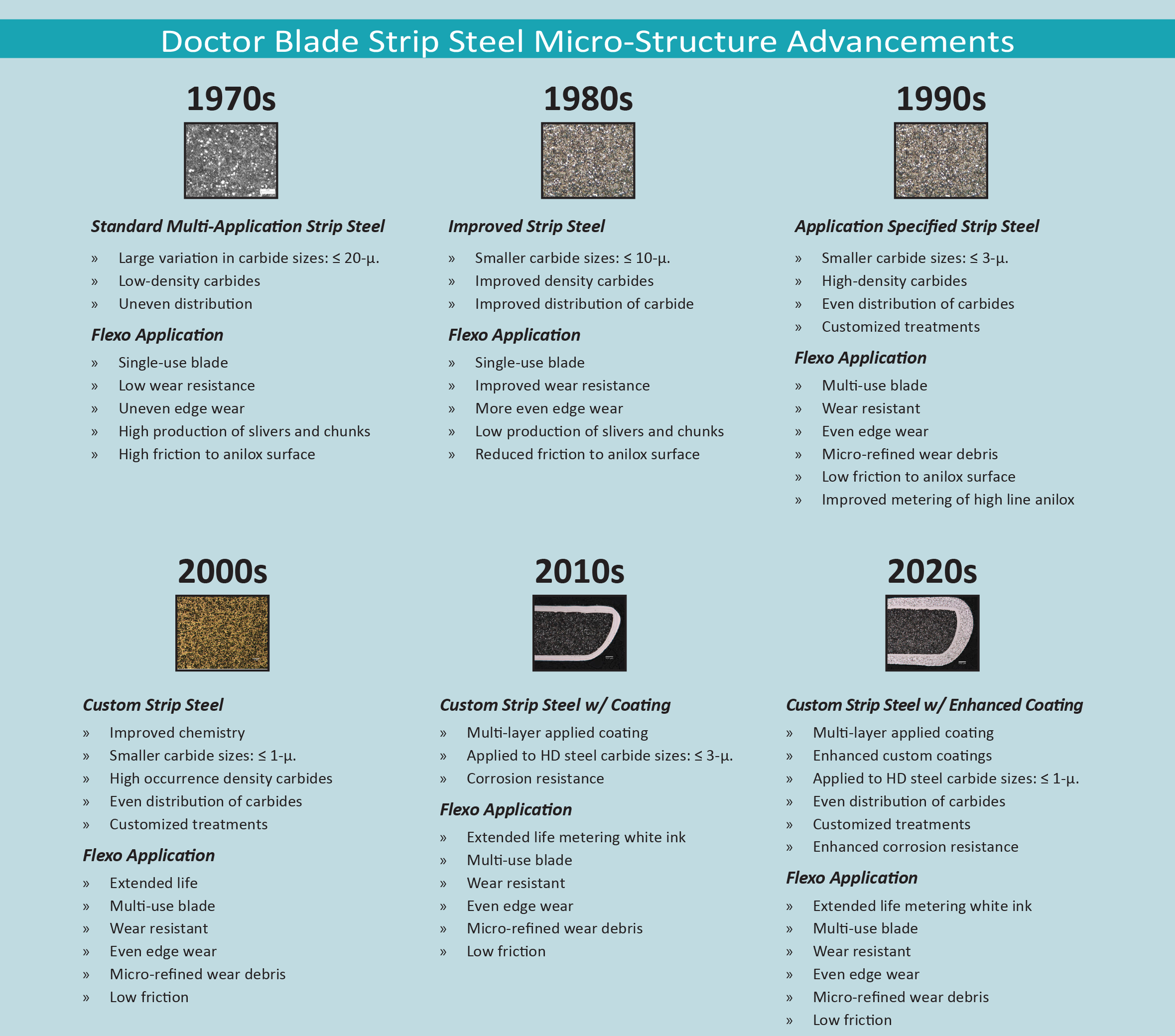

CUSTOMIZED BLADES

In recent years, new specialty strip steels have been developed. Changes to chemical composition combined with modified hot

rolling, cold rolling and tempering has resulted in much slower and even wearing doctor blades while making them less abrasive

against an anilox.

As these new customized blades slowly wear, they yield a fine micro powder rather than anilox-damaging slivers and chunks. In most cases, extended blade life is a result of a higher occurrence of ever smaller, harder and evenly distributed micro particles in the steel’s composition. These materials are far less hard than the ceramic on an anilox.

A pressroom producing high-definition flexography at high speeds can now use one top performing blade for multiple days, on multiple jobs, in place of 10 or more single-use blades—even on white inks. Their higher cost is easily justified, as waste and downtime are reduced and annual blade spends drop. They also require a lot less handling, thereby reducing safety concerns, while achieving a 10-fold reduction in the disposal of used blades.

Developments leading to new types of doctor blade steel did not happen overnight. It is the result of an evolutionary response over many years to changes made to flexography’s ink transfer process—changes to anilox, ink metering systems, inks and new, faster and better controlled press technology.

Today, a majority of flexo pressrooms recognize doctor blades as a truly key process control mechanism. Few still buy blades on price. Instead, buyers do the math. The right blade matched to your press can achieve real and sustainable savings. Check with your doctor blade supplier. They can help you select the best one for your application.

FLXON / SWEDEV offers a wide range of high-quality steel, coated, and plastic doctor blades. We can help you find the best one for your application. If you need help with assessments or training for the best doctor blade solution, contact one of our experts for a consultative evaluation. Our team will be able to help you with solutions.

Download Technical Article

Refining Doctor Blade Technology

Recent Comments