HD FLEXO Doctor Blades

High Demand / High Definition

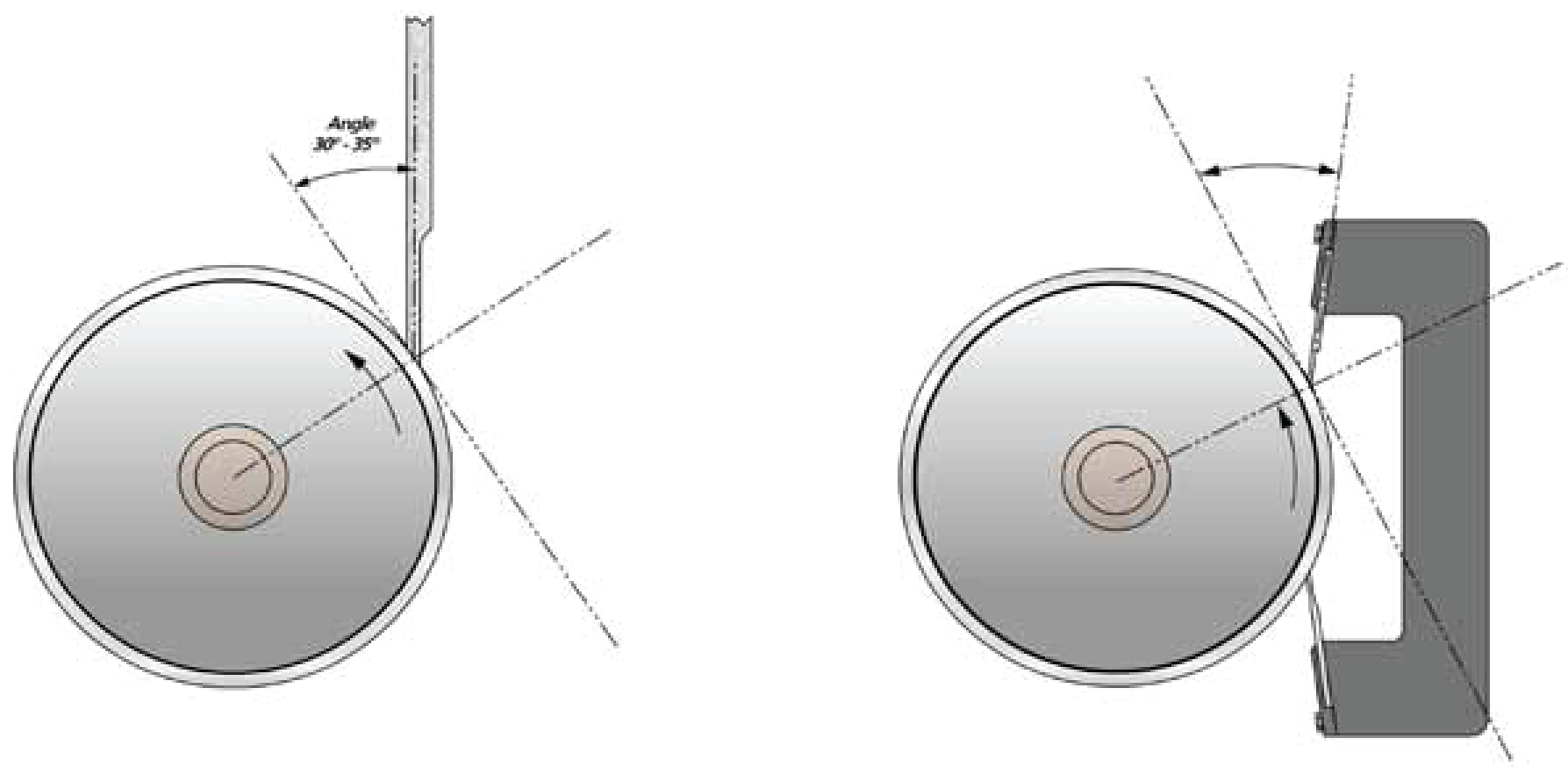

The core purpose of a doctor blade in the flexo process is to remove excess ink from the anilox surface; to leave behind a perfectly smooth ink film for transfer to the image on the plate and to do this without damaging the anilox. The most precise and even metering takes place when the blade makes contact with the anilox in the reverse or sheering position at an angle between 30° – 35°.

In the past 40 years, no print method has advanced more than flexography. Compared to its primary rivals of offset and rotogravure, 1970s flexo was crude—and so were the results. Its primary advantage was price. In fact, like me, you may recall that some of the award-winning frozen food packaging at a 1970s FTA Forum was better viewed from a distance, so the process printed image would gain resolution.

Beginning in the early 1980s, all areas of flexo became much better at printing solids and line work. Still, printers struggled with screens and process.

Today, flexo successfully competes with rotogravure and offset in all market segments and does so based on quality at a competitive price. Success did not happen overnight. Instead, a lot of changes have taken place to the important ink management and ink transfer variables.

FORMULATING STEEL TO MEET THE NEEDS OF HD FLEXO METERING…

1. CHEMISTRY

Doctor blade steels are ferrous or Iron based with some amount of Carbon plus other ingredients like Manganese, Molybdenum, Silicon, Chromium, Nickel, and so on. The ingredients and the amount of each included in a melt determines key performance characteristics, such as hardness and wear resistance, as well as the corrosion resistance each type of steel will have. These ingredients make up the chemical composition of each type or grade of steel.

2. TREATMENTS

Following the melt in which the ingredients are joined together, treatments such as hot rolling, cold rolling and tempering determine the quantity, size and distribution of carbides and other ingredients forming the steel’s micro-structure. The sequence, magnitude and duration of each treatment have as much to do with steel’s performance as a doctor blade, as does its chemistry. When treatments vary, steels with the same chemistry will perform differently.

3. FINISHING

Precise straightness, flatness and edge finishing determine if the blade will sit flat in the holder’s clamp, if the blade will make simultaneous anilox contact or meter consistently from start to stop.

At the top of the list of developments is the anilox roll moving from a high line count of 360 lpi on an engraved and chrome plated surface, up to 1,200 lpi on laser engraved ceramic. This move allowed a significant reduction in anilox surface ink film. In turn, the raised image or dot on the plate can now collect ink from the anilox without being overwhelmed; thereby avoiding dot gain or dirty print even on longer runs. Each of the many advances made to the process elements of anilox, plates, inks, ink delivery, substrates and so on, were matched by prepress and press technology advances. In most instances, these advances were evolutionary in that they happened over time. Often an advance in one area enabled another area to improve.

HD FLEXO PRESS

In a recent interview, a major wide web flexo printer in Pennsylvania said it expanded capacity with a new high speed 10-color CI press from Bobst, not so much because of speed, but because of the press’s ability to achieve and maintain the highest quality print from the moment the press is running until the job is finished. While speed is important, it follows concerns for quality and an ability to change 10-color jobs in as little as 15 minutes; a feat made possible as a result of the press’ Graphic Positioning System. Printers can efficiently and profitably run 360,000 ft. over eight jobs, ranging from 10,000 ft. to 50,000 ft., all in a single eight-hour shift. Being able to run top quality short run and long run jobs with little waste and downtime enables them to be more competitive in more markets. This example of new HD flexo technology is the result of the combined advances of many small and not-so-small process element improvements made over many years.

HD DOCTOR BLADE

Like all flexo process components, the doctor blade has evolved to the point that many blade materials, commonly used in 1980, are no longer available. To understand the driving forces in this evolution, it’s important to first review the fundamental function of a doctor blade. The core purpose of a doctor blade in the flexo process is to remove excess ink from the anilox surface; to leave behind a perfectly smooth ink film for transfer to the image on the plate and to do this without damaging the anilox. The most precise and even metering takes place when the blade makes contact with the anilox in the reverse or sheering position at an angle between 30° – 35°, with the least amount of contact area.

WEAR RESISTANCE

An important quality of doctor blade steel that differs from other strip steel applications is wear resistance. Wear resistance is the ability of a material to keep its original surface. The wear of a doctor blade’s edge is mainly abrasive – the result of scratching. The wear resistance of steel is affected by:

- Hardness of the steel matrix

- Presence of carbides

- Size and distribution of carbides

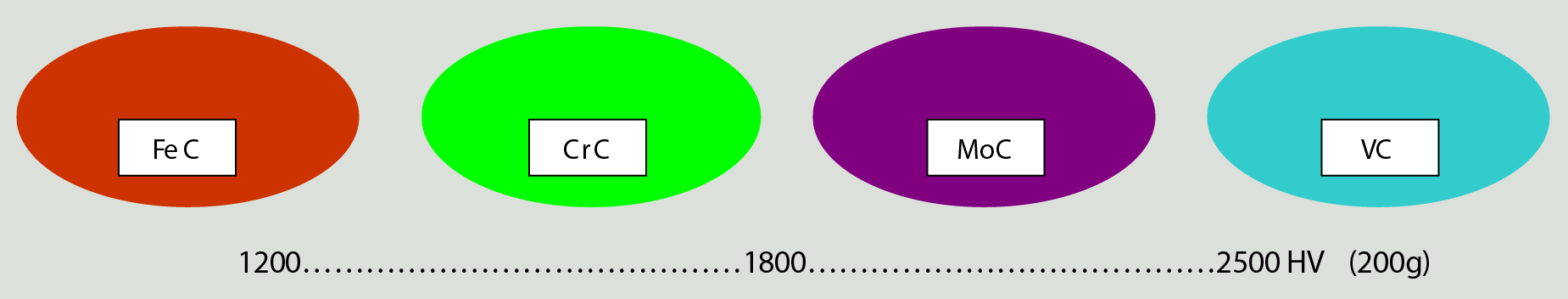

Carbide = Compound of carbon with one or more metallic elements e.g. Iron, Chromium, Tungsten, Molybdenum, Vanadium

Carbides are relatively hard and increase wear resistance measured in VICKERS (HV)

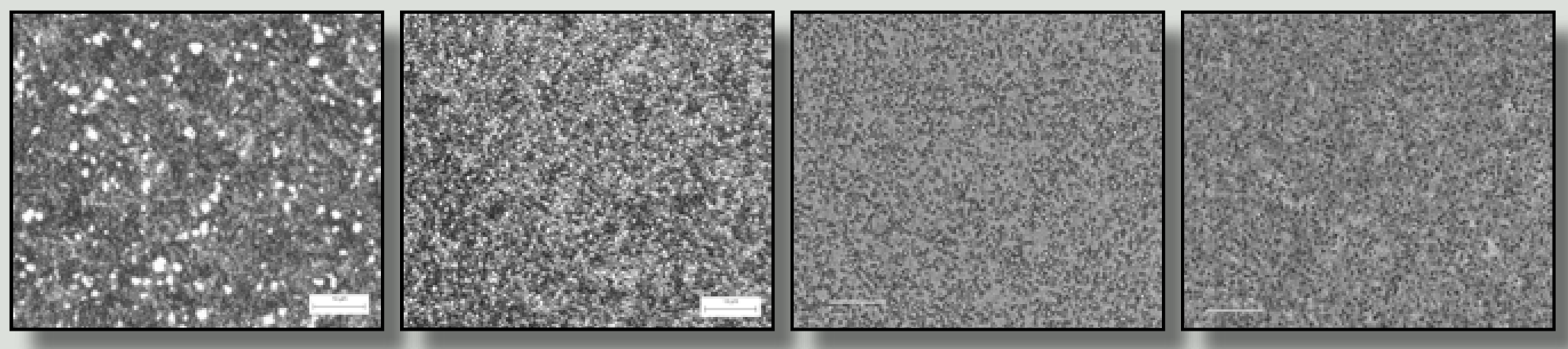

THE QUANTITY & DISTRIBUTION OF CARBIDES

This series of micro photos of doctor blade steels, each with essentially the same chemistry and carbon compound, went though a different series of treatments. Note: each photo is the same magnification and carbides are the white elements.

While the core purpose of doctor blade metering hasn’t changed, the environment in which the blade functions has. In 1980, many printers only knew they used a steel doctor blade but didn’t know what kind of steel or why they weren’t using plastic. While some pressrooms still don’t know the answers to these questions, most flexo printers do. As the specific process environment evolved, so has the doctor blade. The blade materials used by flexo printers 20 or 30 years ago, are simply not compatible with today’s application requirements.

In the new environment of HD Flexo, an ideal doctor blade must:

- Engage a 1,000 cpi anilox surface without damaging it

- Operate at press speeds in excess of 1,000 fpm with less drag, less friction

- Wear slower and more evenly with debris smaller and less threatening to thin walls of high line anilox

- Perform over time in an extended gamut press environment

- Meter a wider range of inks and coatings including UV, EB, metallic, florescent, pearlescent, thermal chromatic, as well as traditional solvent and water based ink

- Resist flex under pressure

COATED, MICRO-REFINED CARBON STEELS

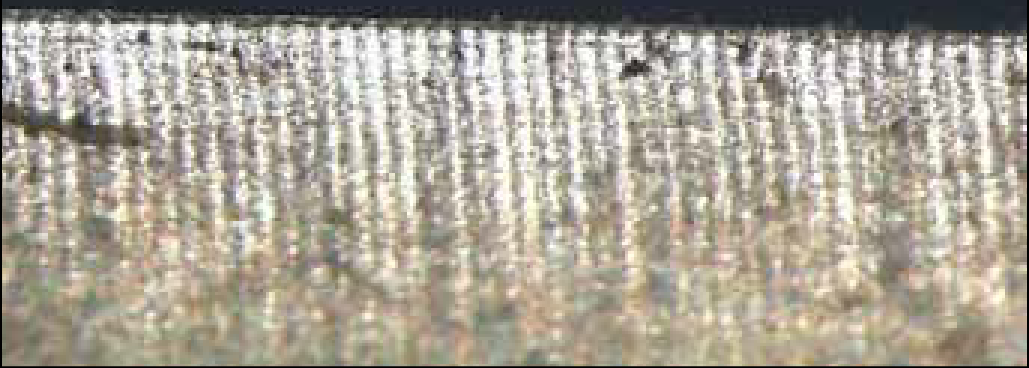

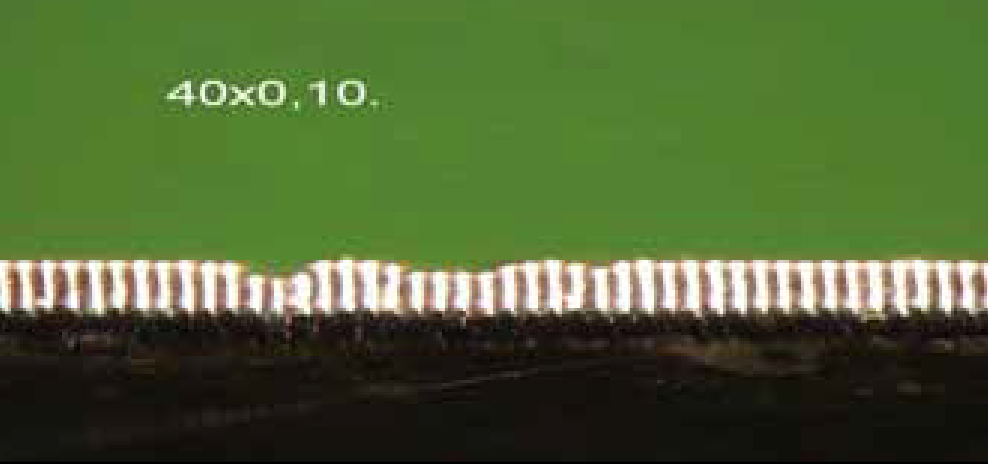

New applied engineered coatings achieve a lubricating effect lowering friction and wear to the anilox, as well as the blade. They prevent threatening hairs or slivers from forming along the doctor blade’s edge. The coating is softer than anilox ceramic and prevents ink and debris form sticking behind the blade. The photo on the left shows such a coating over carbon steel, while the photo on the right shows a similar coating over a Chromium carbon steel. Enhancing micro-elements have been added to the coatings to further reduce friction and wear allowing blades to run millions of feet with little or no wear at very high speeds.

MATERIAL SELECTION → STEEL

In 2013, there is little debate concerning the benefits of steel over plastic or fiber materials. No other material can achieve sustained uniform precision metering as well as steel. In the past, that was the end of the discussion. Printers purchased “steel” metering blades, full stop. They had no idea what type of steel. The flexo environment in which a blade metered in the 1980s, easily tolerated the use of inexpensive, literally run-of-the-mill carbon steel. Chrome anilox line counts averaged 250 and went as high as 360 cpi. Printers expected a blade to strip chrome off an anilox in a few weeks. Metering different inks and coatings from a high line count anilox at speeds close to 2,000 fpm is a very different challenge. Fortunately the doctor blade industry has made significant advances to develop new materials with customized executions tailored to meet the challenge of HD Flexo.

Corrosion Resistance can be an application specific requirement for many pressrooms. This quality can be achieved by including chromium in the steel’s chemistry, which forms a protective oxide layer on the steel’s surface. Nickel and Molybdenum act to stabilize this layer.

Anilox lines in the edge of highly structured steel rich in micro-carbides.

Anilox lines and chipping in low quality steel with few carbides.

METALLURGICAL ADVANCES

In the past, doctor blades were made from previously run flat strips of steel manufactured for use in a wide range of industrial applications. As a result, the steel’s metallurgic qualities, or characteristics, were not specifically aligned to the task of a doctor blade. Doctor blade converters purchased steel strips from various steel mills around the world that they thought would meet the needs of their customers. Because many of their customers were not experienced or informed about the advantages of different types of steel in terms of metering, defect avoidance, process control and so on, many made purchasing decisions based on price. As a result, much of the steel used to make doctor blades was lower cost grades, which seemed to work well enough, when in fact it was contributing to production waste.

BEST BLADE FOR YOU?

Thirty years ago, blade selection was simple. The purchasing person hunted down the lowest cost strip steel at the dimension required for the blade holder on a PCMC or Kidder 660. “…Oh yea, can you make it Swedish blue steel if you’ve got it!” Partnering with a qualified doctor blade provider is a smart business strategy …Today, the doctor blade is recognized as an integral process element of flexography. The quality and productivity demands of today’s flexo require printers to partner with qualified doctor blade suppliers who can help find the best blade for a specific application challenges. A qualified supplier is one that is deeply engaged in product development, including exploring customized steel chemistry and treatments that will result in a blade that will perform best for your particular application. Such companies offer a range of blade materials, dimensions and edges, as well as technical assistance and operator training to assure optimum performance. Their staff includes metallurgical engineers as well as printers. To assure product quality and consistency, every step in the manufacturing process, from steel formulation to the finished product in the box, is governed by a strict ISO certified quality assurance program. Fortunately, in today’s world of HD Flexo, there are new technology doctor blade materials that outperform cheaper quality steels every time. They last longer, reduce mid-run press stops, prevent print defects, reduce press downtime and add life to an anilox roll. Many printers using this new class of HD Doctor Blades report spending less on blades.

If you need help with assessments or training for the best doctor blade solution, contact one of our experts for a consultative evaluation. Our team will be able to help you with solutions.