Cuchillas

Nuestra gama de cuchillas SWED/CUT® de carbono microestructurado, acero inoxidable y acero revestido altamente refinado está desarrollada para funcionar mejor y satisfacer las necesidades específicas de sus aplicaciones de impresión y revestimiento.

Cuchillas Altamente Especializadas para una Vida Más Larga

Procesos

Flexo, Roto, Offset Coaters, Hot Melt, Cold Seal, Laminaciones

Aplicaciones

Banda Angosta, Banda Ancha, Cartón Plegable, Corrugado

Segmentos

Envasado de alimentos, fundas retráctiles, bolsas, etiquetas y rótulos, envases farmacéuticos y médicos, envases de líquidos, sobres, papel de regalo, revestimientos de paredes, revestimientos especiales

Tipos de Tinta

Agua, Solvente, UV, EB, LED

Cuchillas – Flexo, Roto, Recubrimientos, Laminaciones

FLXON es el distribuidor exclusivo de rasquetas de rendimiento SWED/CUT® en América del Norte, que incluyen una variedad de materiales para rasquetas que van desde la confiabilidad económica hasta las opciones de alto rendimiento, todo diseñado para aumentar el rendimiento de su sala de impresión. SWED/CUT® está fabricado con aceros al carbono, inoxidables y revestidos de alta calidad conocidos por sus estructuras microrefinadas y el desgaste lento y uniforme de los bordes que son de mayor resistencia, reducen la fricción y exhiben menos flexión para lograr una limpieza más limpia.

Descargue la guía de selección de SWED/CUT®

La Opción Segura y Confiable en Cuchillas

Mejor Calidad

Una gama de aceros revestidos, inoxidables y al carbono de alta calidad, conocida por sus estructuras microrefinadas y su desgaste lento y uniforme de los bordes.

Dimensiones Precisas

Todas las tolerancias físicas para los tratamientos de ancho, grosor, largo y borde se logran bajo un estricto programa de garantía de calidad CERTIFICADO POR ISO.

Medición Mejorada

Disminución de fricción, mayor resistencia y menor flexibilidad ayudan a lograr una mejor limpieza durante períodos más prolongados, lo que evita defectos de impresión como aumento de puntos y salpicaduras.

Servicio al Cliente:

(800) 756-6474

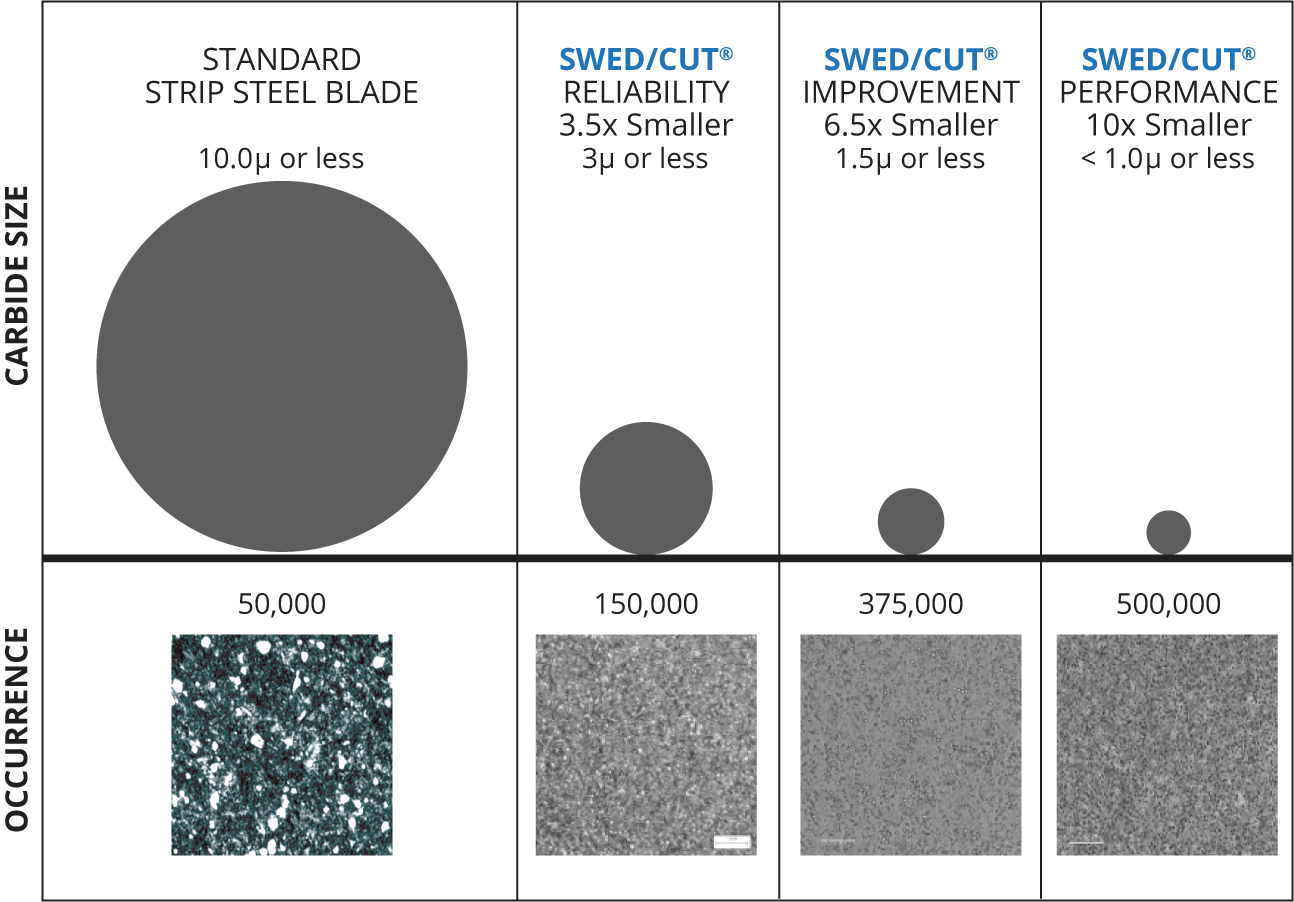

La Microestructura es Importante

En comparación con las tiras de acero estándar, la microestructura de SWED/CUT® está definida por partículas de carburo pequeñas y uniformemente distribuidas que aseguran un desgaste lento y uniforme de los bordes, baja fricción y una formación uniforme de la película de tinta. Para usted, eso significa una rasqueta de mayor calidad que reduce la probabilidad de defectos de impresión comunes, reduce el desgaste de sus rodillos anilox y le permite hacer funcionar sus cuchillas por más tiempo.

La cantidad y el tamaño de los carburos son clave para una excelete cuchilla

Prensas Compatibles

SWED/CUT® supera continuamente a otras marcas de rasquetas en las prensas flexográficas y de rotograbado de mayor rendimiento de la industria.

Bobst, Mark Andy, Windmoeller & Hoelscher (W&H), Nilpeter, Uteco, MPS, Fischer & Krecke (F&K), Harris & Bruno, Tresu, Comexi, Koenig & Bauer (KBA), Allstein, Aquaflex PCMC, Omet, Heidelberg, Primoflex, Retroflex, Soma, Absolute, Gallus, Expert, Pannier, Sobu, KYMC, Bonard, Comco, Printco, FLSmidth, Schiavi, W&D, Kidder, Rotomec, Cerutti, Hsing Wei and many others.

Dimensiones

Nuestras rasquetas de alto rendimiento se fabrican en una amplia gama de anchos, largos y espesores, especialmente diseñadas para satisfacer las necesidades de su sala de impresión.