FLEXO 101

Diverse, Yet Compatible:

Containment Blades, Doctor Blades, & Back Doctoring

Third in a 5 Part Series on The Importance of Basic Process Element

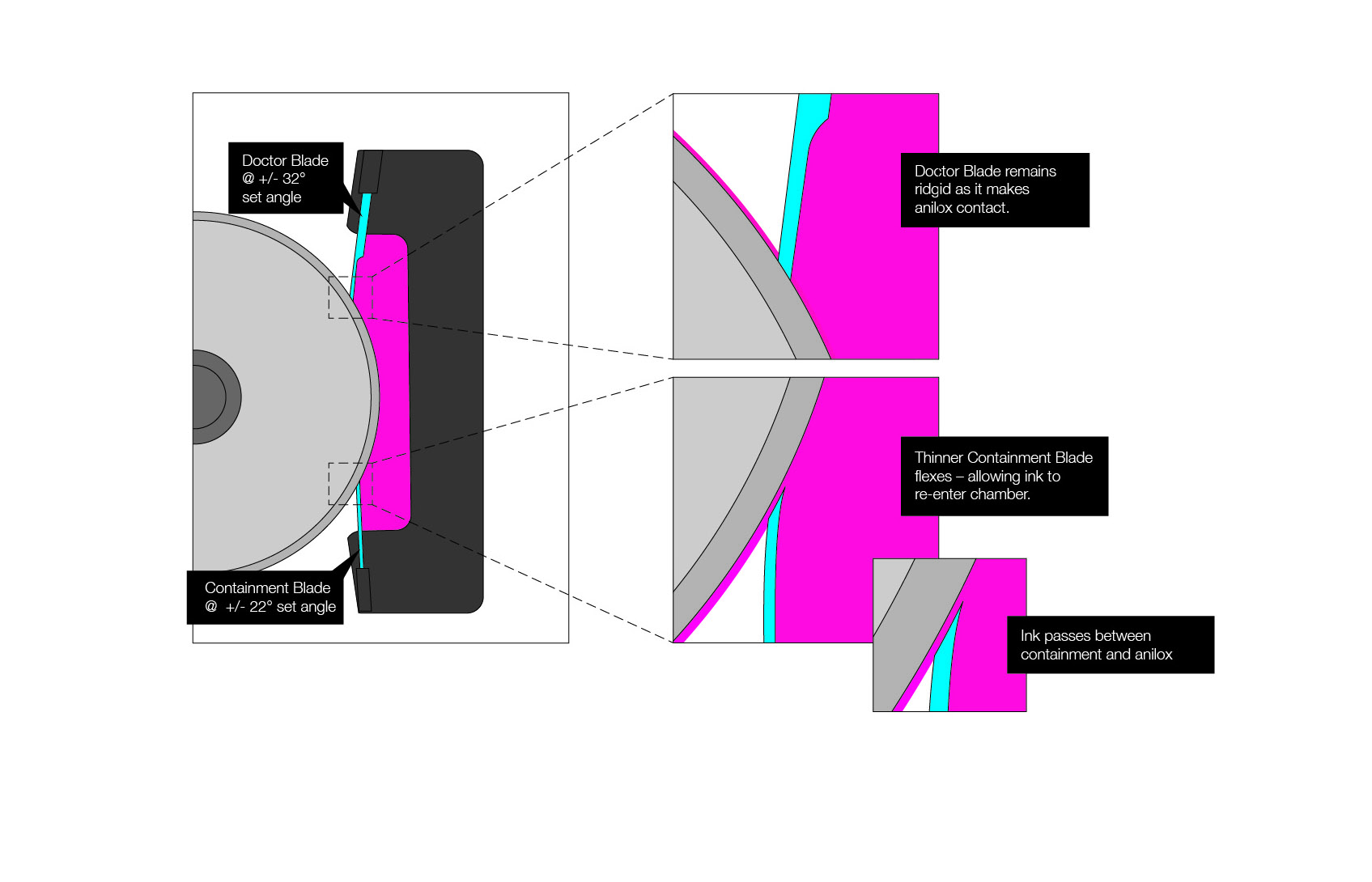

Have you ever asked yourself, “Should I be using the same blade in both positions?” The short answer is—no! Here’s why. Fundamentally the purpose of the containment blade is very different than that of the doctor blade. The doctor blade meters ink and the containment blade, well, contains ink in the chamber.

The containment blade is positioned in the chamber opposite the doctor blade; one upper and one lower. Together with end seals, they contain ink within the chamber against the anilox. Ideally, ink leaves the chamber by two ways: within the anilox cell and by return line from the chamber to the ink reservoir or pail. On a press with a central impression (CI) drum, their positions reverse depending on if the chamber is on the up or down side of the CI drum. On the upside, the anilox is turning up, requiring the doctor blade to be positioned at the top of the chamber to meter ink. On the downside, the doctor blade is positioned at the bottom of the chamber to meter the down turning anilox. Again, the containment blade is positioned opposite the doctor blade.

BACK DOCTORING

The biggest difference between these two blades is that unlike the doctor blade, the containment blade engages the anilox in a wiping or positive position. In this position, the blade intentionally is subject to hydraulic lift, allowing ink to pass between the anilox and blade to reenter the chamber. At least that’s the idea. If the containment blade is too stiff or ridged or at the wrong angle, it meters the returning ink, preventing it from reentry and causes back doctoring. While back doctoring can occur when the containment blade is in the bottom or top position in the chamber, it is more pronounced when the containment blade is at the bottom. The returning “metered” ink travels down the blade and drips into the drip pan. Back doctoring is a major industry problem. Not only is it a waste of ink, it causes ink slinging, print defects and makes a housekeeping mess.

PREVENTING BACK DOCTORING

We’ve established the necessity of making sure the containment blade is not the same as the doctor blade, but there are other factors to consider:

Material

Because the containment blade is employed in a wiping position and has a wider contact area allowing more ink to pass between blade and anilox, the confrontation with the anilox is reduced. With this in mind, the containment material does not have to be of the same material or dimension as the doctor blade.

Steel

In recent years, the steels developed to meet the increased demands of HD flexo (high line anilox at high speed) are super refined, slower wearing materials. An additional advantage is that steel in the containment position will wear more in time with the doctor blade. Finally, steel will not imbed into the ceramic or harbor harmful hard non magnetic elements.

Plastics

In the past, plastics were used as containment blade material because they are naturally more flexible than steel at thin gauge. But over time, problems surfaced such as:

- Hard pigment and resin particles can easily imbed into soft plastic materials, allowing these particles to potentially imbed into cells or even contribute to anilox scoring

- When plastics wear, the worn particles imbed into ceramic changing the surface dyne levels

Contact Angle

In the past, the preset contact angle for both top and bottom positions on many chambers was ±32 degrees. This meant chambers could be used on the up or down side of the CI drum. Unfortunately, back doctoring is more pronounced if

the containment blade makes contact at ±32 degrees, which is the ideal angle for metering. Today, many chambers come with the containment blade set to make contact at ±20 degrees. In this angle range with a thinner blade, back doctoring is almost impossible.

Thickness

The containment blade should be thinner and more flexing. The containment blade engages the anilox on its side or face with a wider contact area as compared to a doctor blade. Remember that we want ink to push the blade back away from the anilox, even at high speed, allowing all the surface ink back into the chamber.

Beveled/Lamella/Radius Edge

While a doctor blade may require a beveled or tapered edge to take a thicker more rigid material down to a reduced contact area, the containment blade functions well with a polished radius edge. Remember: We want the contact area of the containment blade to be wide.

Width

When the set angle of the containment blade is less than the doctoring blade, the width of the blade can be the same. However, when the set angle of both blades is the same—usually around 30 degrees—better results may be achieved by increasing the width of the containment by 0.125-in. This added width will cause the containment blade to make contact a bit closer in on the anilox, helping to reduce the actual contact angle. A word of caution: Changing blade width may alter the blade’s interface to the seal and may contribute to end seal leaking. This depends on the width and density of the seal.

OPTIMAL BLADE PREFERENCES

The ideal containment blade should be:

- High quality steel relative to the material used for doctoring

- A thickness of 0.006-in. or possibly 0.008-in., depending on the thickness of the doctor blade

- Radius edge

- Depending on chambers set angle, the same or slightly wider than the doctor blade

The good news is that while the cost of doctor blades has gone up over the years due to technology developments, the price for containment blades should be a bit less. To make sure the containment blade is optimum and compatible with your application, consult with a qualified industry blade supplier.

If you need help with assessments or training for the best doctor blade solution, contact one of our experts for a consultative evaluation. Our team will be able to help you with solutions.

Download Technical Article

Containment Blades, Doctor Blades & Back Doctoring (3 of 5)